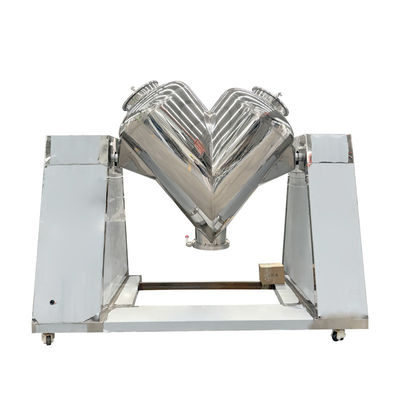

Máy trộn loại V

Mô tả sản phẩm

Máy trộn loại V là một thiết bị trộn bột phổ biến. Cơ thể chính của nó bao gồm hai xi lanh được hàn theo hình dạng V. Trong khi hoạt động, nó xoay xung quanh trục ngang,làm cho các vật liệu liên tục bị khuếch tánNó có hiệu quả trộn cao, dư vật liệu thấp, cấu trúc đơn giản và vận hành dễ dàng.Nó được sử dụng rộng rãi trong các hoạt động trộn đồng bộ của các vật liệu khác nhau trong các ngành công nghiệp như kỹ thuật hóa học, dược phẩm, và thực phẩm.

Nguyên tắc hoạt động

Cơ thể chính của máy trộn loại V được hình thành bằng cách hàn hai xi lanh ở góc 80 ° đến 90 ° thành hình dạng V. Cánh trung tâm chạy qua đỉnh như trục quay.Thiết bị được tạo thành từ một khoangMột số mô hình có thể được trang bị các thiết bị dao bay hoặc giao diện khí trơ.Cấu trúc xem xét cả hiệu quả và sự tiện lợi hoạt động.

Khi máy trộn loại V hoạt động, khoang quay xung quanh trục ngang, khiến các vật liệu trải qua tác dụng trộn ba lần của sự đối lưu,khuếch tán và cắt trong khoang hình V: trộn thông qua luồng dẫn đến các vật liệu định kỳ hội tụ và leo lên giữa hai xi lanh do trọng lực; trộn qua khuếch tán làm cho các hạt khác nhau xâm nhập vào nhau;và cắt trộn phá vỡ các khối thông qua ma sát và nén.

Tính năng sản phẩm

1- Ưu điểm hiệu quả cấu trúc và trộn

- Khoang hình chữ V đối xứng: Thiết kế góc 80° đến 90° tạo thành một quỹ đạo chuyển động không đối xứng.dẫn đến sự đồng nhất cao của trộn, với một số góc chết và dư lượng thấp.

- Hoạt động kháng cự thấp: Cấu trúc hỗ trợ trục trung tâm ổn định. Khi quay, vật liệu ít bị ảnh hưởng bởi lực ly tâm, với mức tiêu thụ năng lượng thấp hơn,làm cho nó phù hợp với hoạt động liên tục lâu dài.

2- Khả năng thích nghi vật liệu và khả năng mở rộng chức năng

- Áp dụng rộng: Nó có thể xử lý các vật liệu bột và hạt, và có hiệu ứng trộn đáng chú ý đối với các vật liệu có sự khác biệt mật độ lớn và dễ phân tầng.Bằng cách cấu hình thiết bị dao bay, các vật liệu nếp nhăn có thể được nghiền nát.

- Chức năng bảo vệ tùy chọn: Một số mô hình đáp ứng các yêu cầu pha trộn các vật liệu dễ cháy, nổ hoặc nhạy cảm với oxy hóa, và tuân thủ các tiêu chuẩn an toàn trong dược phẩm,ngành hóa học và các ngành công nghiệp khác.

3Dễ sử dụng và làm sạch

- Điều chỉnh thuận tiện: Tốc độ quay và thời gian trộn có thể được điều chỉnh chính xác theo đặc tính của vật liệu.Nó có một mức độ tự động cao và hỗ trợ kiểm soát chương trình PLC.

- Thiết kế dễ làm sạch: Nội thất của khoang mịn mà không có góc chết. Vật liệu chủ yếu là thép không gỉ (như 304/316L),và bề mặt được đánh bóng để đáp ứng GMP và các tiêu chuẩn vệ sinh khácNó thuận tiện cho việc tháo rời và bảo trì.

4Ứng dụng cụ thể trong ngành

- Nó đặc biệt phù hợp với các kịch bản với yêu cầu cao về sự đồng nhất của trộn và dư lượng, chẳng hạn như trộn viên thuốc và hạt trong ngành công nghiệp dược phẩm,Trộn phụ gia trong ngành công nghiệp thực phẩm, và chuẩn bị chất xúc tác trong lĩnh vực hóa học.

Các thông số sản phẩm

| Mô hình |

V-30 |

V-100 |

V-200 |

V-300 |

V-500 |

V-1000 |

V-1500 |

V-2000 |

V-3000 |

Tổng khối lượng

(L) |

10-30 |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

Khối lượng hiệu quả

(L) |

5-15 |

50 |

100 |

150 |

250 |

500 |

750 |

1000 |

1500 |

Nạp tải tối đa

Trọng lượng (kg) |

5-20 |

40 |

80 |

120 |

200 |

400 |

600 |

800 |

1200 |

Vòng xoắn

tốc độ (RPM) |

29 |

1-12 |

1-12 |

1-12 |

1-12 |

1-12 |

1-9 |

1-9 |

1-9 |

Động cơ

công suất (kw) |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

| Năng lượng đầu vào |

220V |

380V |

380V |

380V |

380V |

380V |

380V |

380V |

380V |

Tổng quay

chiều cao (mm) |

1200 |

1500 |

1650 |

1800 |

2100 |

2400 |

2700 |

3000 |

3200 |

| Trọng lượng (kg) |

120 |

500 |

600 |

700 |

800 |

1000 |

1150 |

1400 |

2300 |

Nhìn chung

kích thước (mm)

L / w / h |

800*

400*

1200 |

1800*

600*

1500 |

2200*

650*

1700 |

2320*

720*

1800 |

2450*

720*

2000 |

3000*

900*

2300 |

3300*

1200*

2600 |

3800*

1200*

2900 |

4100*

1800*

3100 |

| Nhiều kích thước có thể được tùy chỉnh |

|

Chi tiết hình ảnh

Triển lãm sản phẩm

Bao bì và giao hàng

Tại sao chọn chúng tôi

Về chúng tôi

Hồ sơ công ty

Chúng tôi đã chuyên sản xuất màn hình và thiết bị truyền tải trong 13 năm. ngành công nghiệp màn hình rung động của Trung Quốc hàng đầu ba. và chúng tôi đã làm phù hợp và OEM cho nhiều công ty lớn.Bao gồm cả nhà sản xuất màn hình rung động hàng đầu thế giới, Sweco, Mỹ, chúng tôi có OEM cho khu vực Trung Quốc của mình. Và các sản phẩm của chúng tôi thường được xuất khẩu sang Úc, Thái Lan, Indonesia, New Zealand và các nước khác.