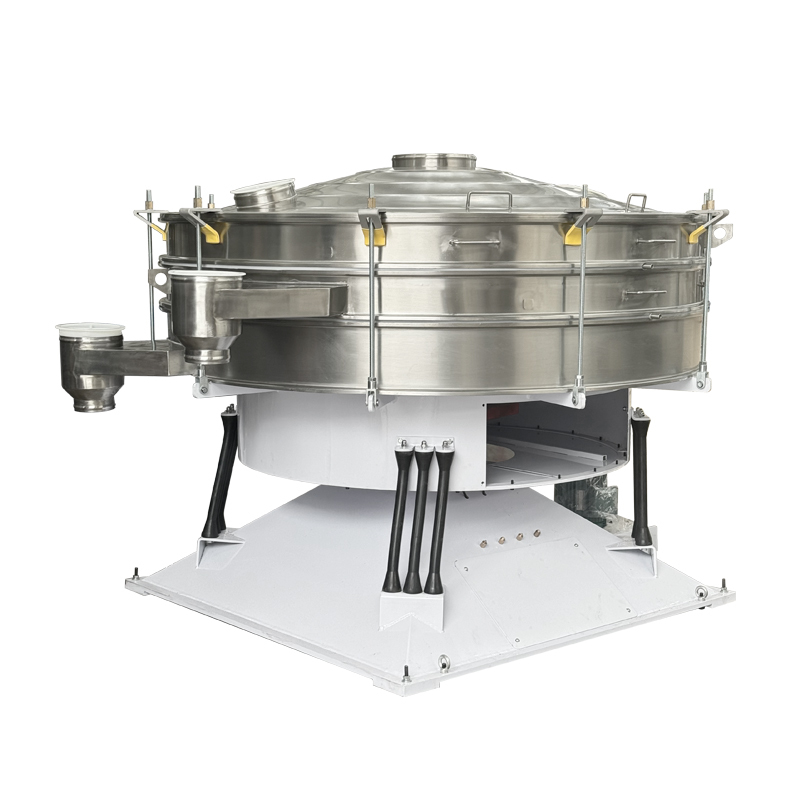

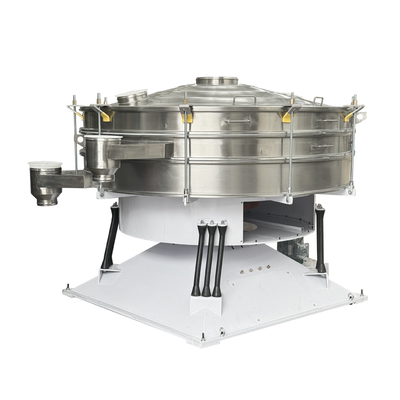

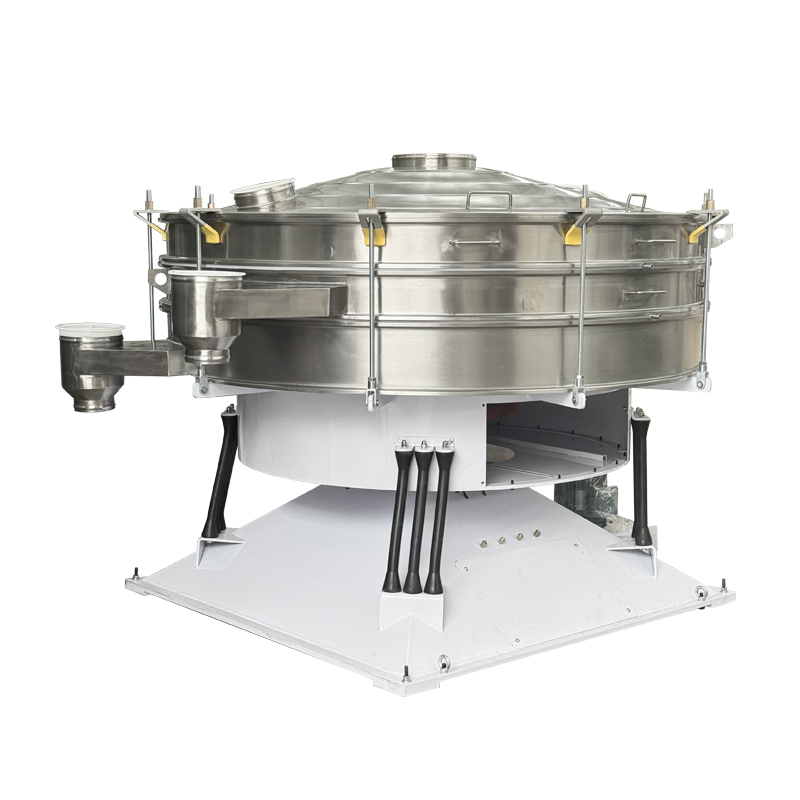

Máy sàng rây lồng rung thực phẩm bằng thép không gỉ năng suất cao

Giới thiệu sản phẩm

Máy sàng rung là thiết bị sàng lọc hiệu quả, được sử dụng rộng rãi trong các ngành công nghiệp như khai thác mỏ, kỹ thuật hóa học, thực phẩm và dược phẩm. Nó áp dụng thiết kế sàng nhiều lớp, cho phép phân tách các vật liệu có kích thước hạt khác nhau đồng thời. Nó có độ chính xác sàng lọc cao, công suất xử lý lớn và tỷ lệ sử dụng cao của lưới sàng. Do chuyển động nhẹ nhàng và vật liệu không dễ làm tắc nghẽn các lỗ sàng, nó đặc biệt thích hợp để xử lý các vật liệu nhớt, dễ kết tụ hoặc dễ vỡ. Đây là một thiết bị nâng cấp để thay thế các máy sàng rung truyền thống và có thể nâng cao hiệu quả sản xuất và chất lượng sàng lọc một cách hiệu quả.

Nguyên tắc hoạt động

Máy sàng rung hoạt động bằng cơ chế truyền động để làm cho thân sàng thực hiện các chuyển động nghiêng và lắc định kỳ. Kết hợp với chuyển động quay ngang và rung dọc nhẹ, vật liệu được phân tán đều và đẩy trên bề mặt sàng. Các vật liệu nhỏ hơn các lỗ sàng đi qua sàng để phân loại, trong khi các vật liệu lớn hơn các lỗ sàng được thải ra dọc theo quỹ đạo. Các thông số chuyển động có thể được điều chỉnh khi cần thiết để giảm tắc nghẽn và cải thiện hiệu quả sàng lọc.

Tính năng sản phẩm

- Độ chính xác sàng lọc cao: Quỹ đạo chuyển động ba chiều cho phép vật liệu được phân tán hoàn toàn, dẫn đến phân loại chính xác hơn.

- Công suất xử lý lớn: Bố cục hợp lý của bề mặt sàng và thiết kế chuyển động giúp tăng cường công suất xử lý trên một đơn vị thời gian.

- Ít có khả năng làm tắc nghẽn sàng: Chuyển động nhẹ nhàng làm giảm độ bám dính của vật liệu vào lưới, làm cho nó đặc biệt thích hợp cho các vật liệu nhớt và dễ kết tụ.

- Khả năng thích ứng mạnh mẽ: Biên độ và tần số chuyển động có thể được điều chỉnh, làm cho nó phù hợp với các kích thước hạt và tính chất khác nhau của vật liệu.

- Phân loại nhiều lớp: Hỗ trợ thiết kế sàng nhiều lớp, cho phép phân tách đồng thời nhiều cấp độ kích thước hạt.

Thông số sản phẩm

|

Model

|

Tầng

|

Đường kính thiết bị

|

Diện tích lưới sàng (m2)

|

Tần số

(v/phút)

|

Độ dốc sàng

(độ)

|

Lưới sàng

|

Biên độ

(mm)

|

Công suất

(kw)

|

|

EYBS-600

|

|

|

|

|

|

|

|

|

|

EYBS-1000

|

|

|

|

|

|

|

|

EYBS-1200

|

|

|

|

|

|

|

|

EYBS-1500

|

|

|

|

|

|

|

|

EYBS-1800

|

|

|

|

|

|

|

|

|

EYBS-2000

|

|

|

|

|

|

|

|

EYBS-2600

|

|

|

|

|

|

|

Máy có thể được tùy chỉnh dựa trên nhu cầu của bạn

|

Sơ đồ dây chuyền sản xuất

Trình bày chi tiết

Ứng dụng

Hóa chất, thực phẩm và gia vị, nhựa, khai thác mỏ, dược phẩm, chế biến gỗ và ván ép, luyện kim, cao su, thức ăn chăn nuôi, phân bón, đường và các ngành công nghiệp, v.v.

Đóng gói và vận chuyển

1. Gói hàng:

Chọn một hộp gỗ với vật liệu đóng gói chắc chắn để cung cấp sự bảo vệ và hỗ trợ đầy đủ.

2. Logo và tài liệu:

Đánh dấu rõ ràng tên, kiểu máy, trọng lượng, kích thước và số lượng thiết bị trên bao bì.

3. Chuẩn bị các chứng từ và chứng chỉ vận chuyển cần thiết, chẳng hạn như hóa đơn, danh sách đóng gói, hợp đồng vận chuyển và giấy chứng nhận bảo hiểm, v.v.

4. Phương thức vận chuyển:

Chọn phương thức vận chuyển thích hợp, chẳng hạn như đường biển, đường hàng không hoặc đường bộ, đưa ra lựa chọn của bạn dựa trên điểm đến và yêu cầu về thời gian.

Tại sao chọn chúng tôi

Về chúng tôi

Câu hỏi thường gặp

Q1: Máy sàng lồng rung điện phù hợp với phạm vi kích thước hạt nào?

A: Máy sàng lồng rung điện phù hợp với nhiều loại kích thước hạt, từ các hạt mịn cấp micron đến các hạt thô cấp milimet và có thể được sàng lọc và phân loại.

Q2: Độ chính xác sàng lọc của máy sàng lắc điện là bao nhiêu?

A: Độ chính xác sàng lọc của máy sàng lắc điện phụ thuộc vào các yếu tố như kích thước lỗ sàng, tính chất vật liệu và thông số sàng lọc. Thông thường, nó có thể đạt được độ chính xác sàng lọc cao và có thể đáp ứng các yêu cầu sàng lọc của các kích thước hạt khác nhau.

Q3: Ưu điểm của Máy sàng lồng rung điện là gì so với các loại thiết bị sàng lọc khác?

A: So với các loại thiết bị sàng lọc khác, Máy sàng lồng rung điện có độ chính xác sàng lọc, hiệu quả sàng lọc và tính linh hoạt cao hơn.